Build your own velomobile in no time: simple, lighter, faster

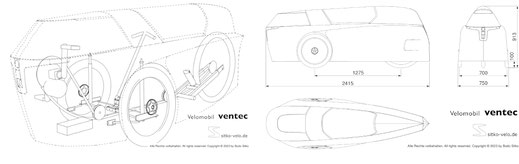

Velomobil ventec

Lightweight in wood

Good visibility

On tour

Learn more about

ventec

Learn more about

ventec  Close

Close

ventec surprises with outstanding features

Speed: The body shape and ventilation system were developed in a wind tunnel. The streamlined shape and small frontal area result in a CdA value of 0.047 m². The low center of gravity

and tuned chassis keep the vehicle safely on track.

Convertible: Depending on your preference and the weather, the ventec can be driven with the top down or as an open convertible. The top, which weighs just 650 grams, can be opened and

closed or rolled up and stowed in the vehicle.

Weight: Without electric assistance and with weight-optimized components, the ready-to-use Ventec weighs just 26 kg, putting it in the weight range of carbon velomobiles.

The lighting elements are visible from a distance due to their height. Visibility to the front is exceptionally good thanks to the high headlights and compact front end. The driver has

a very good field of vision thanks to the flat A-pillars.

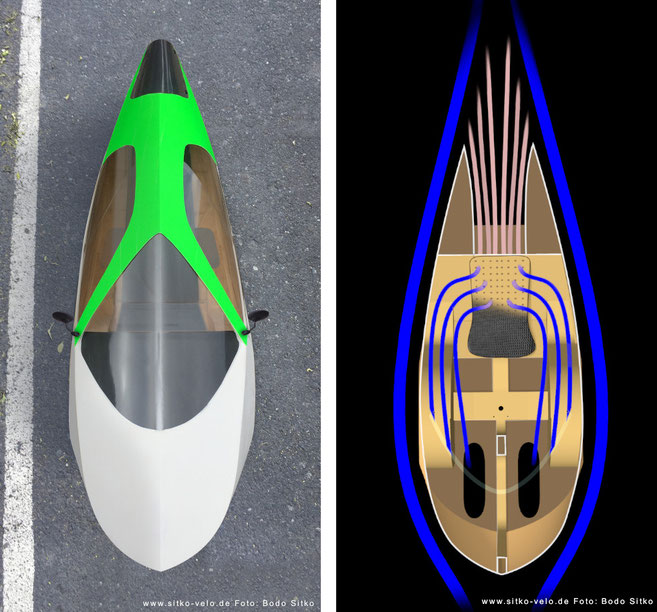

The ventilation ensures clear visibility in every situation. Used air is directly and effectively extracted through the perforated seat – keeping clothes and back dry; no sweating!

The interior offers space for people between 1.50 m and 1.95 m tall. The integrated, internally adjustable rearview mirrors create no air resistance. The smartphone, sound, and ventilation are optimally positioned. Thanks to the generous luggage capacity of approximately 60 liters, larger purchases or vacation luggage can be easily stowed.

The components are safe and proven components from reputable manufacturers. They are listed in the blueprint and can be ordered online.

...and all this for only €2,600

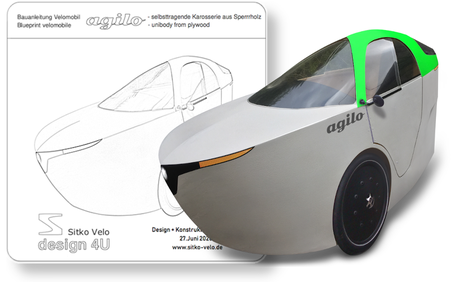

Velomobil agilo

Multi-talented

Learn more about

agilo

Learn more about

agilo  Close

Close

agilo – a multi-talent

Easy game: Thanks to the low weight and aerodynamically optimized body, you'll always be ahead of the game. Additional power is provided by an electric assist system that can be easily

integrated into the bottom bracket or rear wheel hub.

The cabine is suitable for people between 1.50 m and 2.00 m tall. The distance to the bottom bracket and the seat height can be individually adjusted to your height. The cabin offers

protection on all sides, as the solid connection between the seat structure and the body creates a very stable and rigid passenger compartment. Next to and behind the seat is a spacious

storage space of approximately 80 liters for groceries and all kinds of luggage.

The ventilation system was developed by Sitko Velo to keep the windows fog-free and the rider dry. A diffuser at the rear of the vehicle uses the suction effect of the airflow to

direct moisture from the interior—especially from the seat—directly to the outside. The windshield and side windows are adjustable and can be opened, ensuring you always have a good view.

Agilo is compatible with common and proven components used in bicycle and velomobile technology. Pre-drilled holes in the body allow for precise installation in the correct position.

The independent suspension provides safe and comfortable riding. Hub or derailleur gears are available, and electric motors can be installed in the rear wheel hub or bottom bracket. The

turning circle diameter is 7.4 m.

...and all this for only €2,500

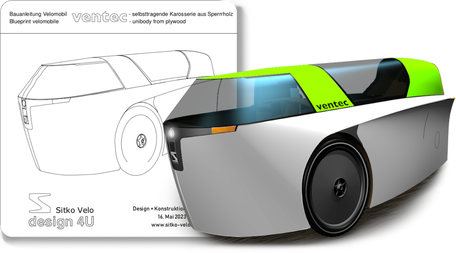

With our construction plans you can successfully build your velomobile

Create your own values

Illuminating images

Learn more about the

blueprint

Learn more about the

blueprint  Close

Close

Create your own value: With our construction plans and your own input, you can build a high-quality yet very affordable velomobile.

The blueprint contains everything you need for successful construction: illustrated and clearly understandable building instructions, 1:1 sewing patterns and a complete material list

of all components.

The contours of the parts are transferred to the plywood sheets using the template wheel. Thanks to the 1:1 scale, you can cut the parts precisely and easily. Registration marks on the

parts ensure correct positioning.

The visual language makes the assembly instructions internationally understandable and takes you step by step to your goal.

Error-free assembly: this is made possible by appropriate holes in the body and ensures the precise assembly of the components.

Frequently Asked Questions - FAQ

Is this project suitable

for me?

Is this project suitable

for me?  Is this

project suitable for me?

Is this

project suitable for me?

If you enjoy crafting, have good craftsmanship skills, and experience working with wood, plastic, and metal: Yes! You should also be well-versed in velomobiles and bicycle mechanics.

How much time do I need for

the bodywork?

How much time do I need for

the bodywork?  How much time

do I need for the bodywork?

How much time

do I need for the bodywork?

This varies greatly from individual to individual, and the creation process also takes time. If you take it easy, you'll have more fun and the result will be better. A timeframe of 4-5 weeks

for the finished body is realistic.

How much are the material

costs for a finished velomobile?

How much are the material

costs for a finished velomobile?  How much are

the material costs for a finished velomobile?

How much are

the material costs for a finished velomobile?

- The painted body including windows: approx. 600 €

- Basic equipment with bicycle and velomobile components: approx. 1800 €

- Electric support from around €600

How light is a wooden

velomobile?

How light is a wooden

velomobile?  How light is a

wooden velomobile?

How light is a

wooden velomobile?

With lightweight plywood, high-quality workmanship, and lightweight components, our velomobiles can easily compete with carbon velomobiles: the fully equipped ventec weighs only 26 kg!

Which plywoods can I

use?

Which plywoods can I

use?  Which plywoods

can I use?

Which plywoods

can I use?

The plywood must meet 3 conditions:

1. Plattenformat mindestens 1220 x 2500 mm

2. Material thickness 3 mm

3. Number of layers: 3

Poplar and ceiba are the lightweight plywoods, with a density of 350-410 kg/m3. Okume is approximately 20% heavier, but also correspondingly more stable. The strength of the different wood species is almost exactly proportional to their density (20% more weight = 20% more strength). The same applies to the material's hardness and thus its workability. To combine the respective advantages, a mix of different plywood species can be useful.

Why 3mm plywood?

Why 3mm plywood?

Why 3mm

plywood?

Why 3mm

plywood?

Because greater wall thickness offers particular advantages: high surface stiffness, better surface tension (stretching), dampened vibration behavior, better protection against heat and cold,

better dimensional stability (denting, warping, wobbling), better correction options (grinding), larger bonding surfaces (force transmission).

Can I use material

thicknesses other than 3mm?

Can I use material

thicknesses other than 3mm?  Can I use

material thicknesses other than 3mm?

Can I use

material thicknesses other than 3mm?

The constructions are based on 3 mm thick plywood. With other material thicknesses, the parts would not fit together. Thicker material cannot be bent as required. Thinner material has only

disadvantages other than its flexibility (see above).

What do I need for

construction?

What do I need for

construction?  What do I need

for construction?

What do I need

for construction?

A room of approximately 12 square meters would be sufficient; something the size of a garage would be ideal. The tools you'll need include a jigsaw, cordless screwdriver, drill, pattern

cutter, cutter, tape measure, square, clamps, sanding block or hand sander, sandpaper, fine-tooth saw, metal saw, flat file, paint roller, workbench, two trestles, and a mounting plate

approximately 2.20 m x 80 cm.

What work steps are

required?

What work steps are

required?  What work

steps are required?

What work

steps are required?

Transferring patterns, cutting, drilling, sanding, soaking, bending, gluing, bonding, filling, painting and assembling components.